ROSEDALE ABBEY VILLAGE England

ROSEDALE ABBEY VILLAGE England

Client: Ryedale District Council

Country: UK

Length of Pipe: 2000 m

No. of Valves: 28

Volume of Flow: 10 litres/second

Specialist Feature: Steep gradients, rocky ground, stream crossings.

The picturesque village of Rosedale Abbey lies deep within the North York Moors National Park – an area of great natural beauty and environmental sensitivity. Very popular with holidaymakers, the village contains peaceful caravan parks and several restaurants and pubs. The population varies greatly between winter and summer.

The village is situated alongside the river Seven and is in a steep sided valley. In the past, inadequate sewerage within the village meant that the risk of polluting the river was always present, particularly so in the summer months.

Having made the decision to install a mains sewerage system to serve the village, Ryedale District Council designers were faced with some difficult problems to overcome. The river and a tributary stream had to be crossed by the sewers and the environmental impact of the construction work had to be kept to an absolute minimum. This meant that fixing pipes to the existing bridges was not acceptable – the pipes had to cross under the deeply cut stream and river.

To use conventional sewerage techniques would have meant pumping stations at each crossing together with some deep trenching works in difficult ground. Iseki were asked to assess the possibility of using The Vacuum Way and were able to offer a cost-effective and well engineered sewerage system. This enabled the environmental impact to be kept to a minimum with shallow, narrow trenches and a single pumping station located away from the attractive village centre.

Vacuum Pipework

Vacuum sewers in polyethylene, sized from 110mm to 160mm diameter, with electro-fusion joints.

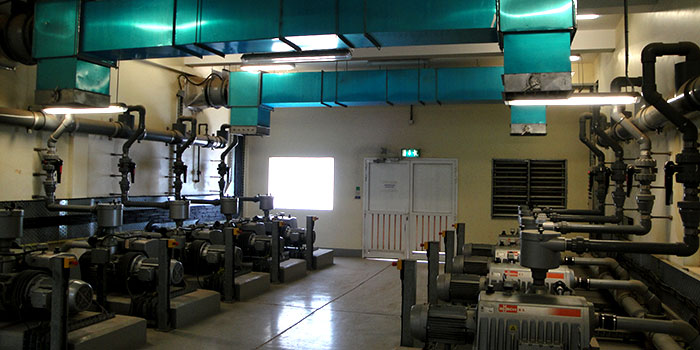

Vacuum Station Equipment

2 liquid ring vacuum pumps each rated at 370 cubic metres/hr.

2 No dry well discharge pumps each rated at

10.5 l/sec duty-assist.

Vacuum collection vessel volume 4.5 cubic metre fully protected with suitable paint and tested to Lloyds certification

Motor control cabinet – fully automatic with programmable PLC. All pumps start in rotation and all conditions are remotely monitored via station telemetry in a central control office, which minimises personnel attendance.

Bespoke valve monitoring system which monitors the open / closed mode of each interface valve located around the village, such that each valve within the village can be individually observed from the collection station.

Exhaust gases are filtered by passing them through a biological filtration unit situated close to the collection station which is within the sewage treatment works site

Summary

The ‘Vacuum Way’ enabled the river and streams to be crossed without the need for separate pumping stations. The shallow trenches offered specific construction advantages on the steep streets of the village. The system is sufficiently flexible to cope well with the wide seasonal variety in sewerage flows.

Possible Applications for Iseki Redivac’s Technology

Rural community sewerage schemes

Industrial developments

Supply bases

Housing developments / compounds

Hazardous waste collection

Airports & military installations

Beach developments

Remote villages

Vacuum sewer crossing river

Vacuum Station building in keeping with the local architecture

Crossover connection

Cost effective solutions to many difficult drainage problems