ADDCAP OFFSHORE BASE, ABU DHABI, UAE

ADDCAP OFFSHORE BASE, ABU DHABI, UAE

Client: ADDCAP

Country: United Arab Emirates

Length of Pipe: 3000 m

No. of Valves: 32

Volume of Flow: 10 litres/second

Specialist Feature: Design allows for on-going development and expansion of base facilities

Vacuum Station

Abu Dhabi Drilling Chemicals and Pipes are suppliers of materials to the oil and gas industry. Following the decision to move from their island base a few miles off the coast, a new site was selected on the mainland close to Abu Dhabi city. This new supply was to be located on a flat low lying area of desert sand adjacent to the Gulf. To be built on the new site was a central office block together with storage facilities, with warehousing that would develop as demand required. Provision was to be made within the vacuum sewer network design for the future addition of an accommodation block for employees on the base.The site measured 1km by 1km and was flat with saline ground water at approximately 1meter deep. Be-cause of the widely spaced buildings and the poor ground conditions, a conventional sewerage system would have been expensive and hard to install. Also, with the development taking place over a number of years, a large degree of flexibility was required such that changes to layout and flow patterns could be ac-commodated by the system.

GRP Collection Sump with concrete anti-floatation collar

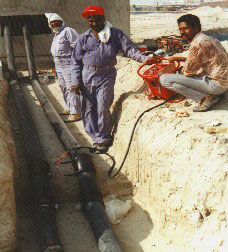

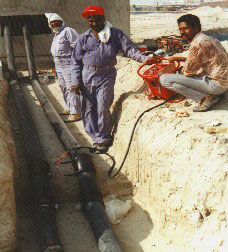

Vacuum Pipework

The polyethylene pipework around the Base ranges in size from 90mm to 160mm diameter.

Vacuum Station Equipment

2 No liquid ring vacuum pumps each rated at 370 cubic me-tres/Hr (Nash) acting in duty/assist configuration, served by a water cooling unit to ensure peak efficiency.

2 No dry well discharge pumps each rated at 10 l/s duty/standby

Vacuum collection vessel volume – 16 cubic metre fully pro-tected with epoxy coating and tested to Lloyds certification

Motor control cabinet – fully automatic with programmable PLC. All pumps start in rotation and all operating conditions are monitored via station telemetry.

Bespoke valve monitoring system which monitors the open / closed mode of each interface valve located around the site.

Exhaust gases are filtered by passing them through an activat-ed carbon filtration unit and are finally discharged outside of the collection station building.

Shallow vacuum pipework entering station

Summary

The Vacuum Way proved the ideal solution – pipes were in-stalled at shallow depths, largely above the sea water table and the inherent flexibility of the system in terms of future de-velopment was greatly appreciated by the Client.

Possible Applications of the Vacuum Way

Rural community sewerage schemes

Industrial developments

Supply bases

Housing developments / compounds

Hazardous waste collection

Airports & military installations

Beach developments

Remote villages

ADDCAP OFFSHORE BASE, ABU DHABI, UAE

ADDCAP OFFSHORE BASE, ABU DHABI, UAE